How much do you know about the intelligent control system of welding robots?

May 04,2023 | TOPTEK

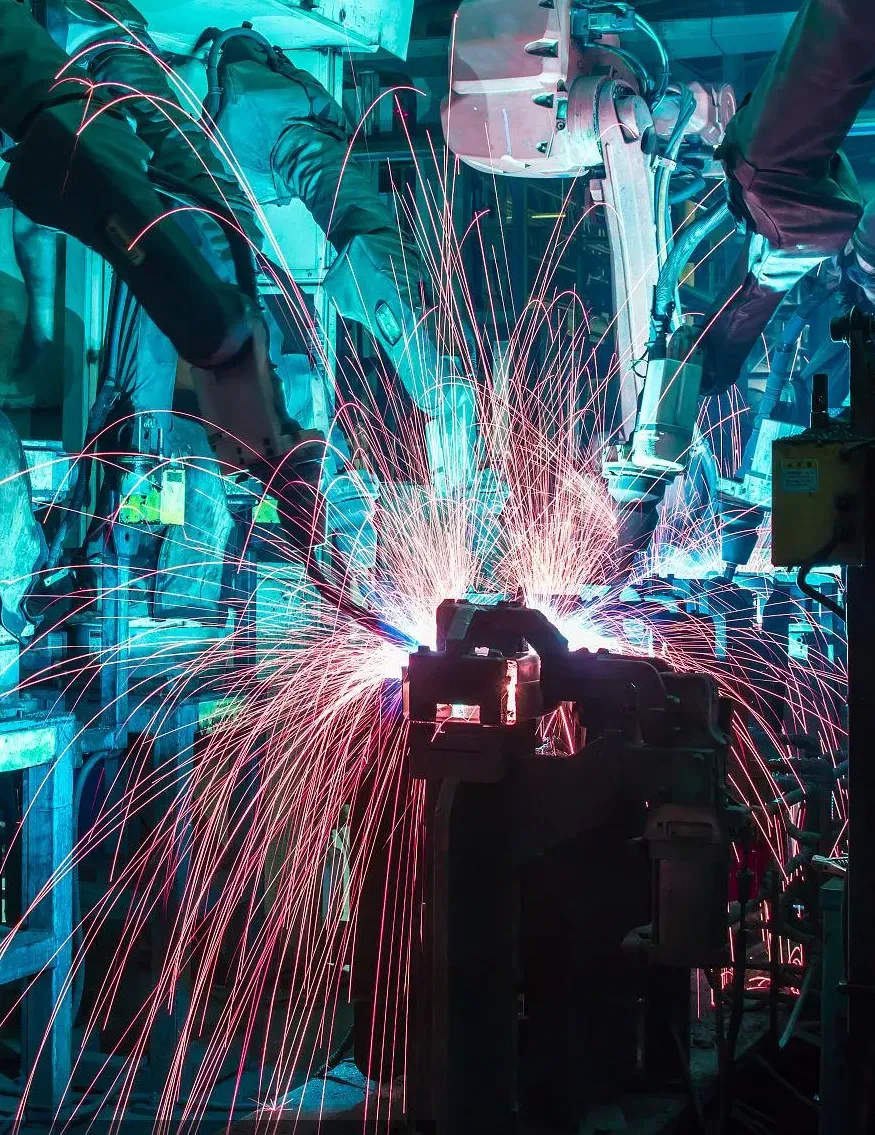

With the continuous improvement and development of welding technology, welding robots have been qualitatively improved in terms of service life, welding quality, welding effect, and welding speed. The wide application of welding robots has improved the automation level in various fields. The various advantages of the robot benefit from its intelligent control system.

1. Significance of welding robot intelligent control system:

The intelligent control system of the welding robot is equivalent to the human brain. With a certain memory capacity, it can memorize and store motion trajectory and welding information. welding.

The intelligent control system adopts 32-bit CPU control, which improves the speed of motion interpolation and coordinate transformation of the welding robot, and flexibly responds to weldments in different fields. Welding workers set the movement trajectory through the teaching pendant, and the intelligent control system performs intelligent identification. And automatically invoked when processing the same weldment.

2. Structure of welding robot intelligent control system:

The welding robot intelligent control system is mainly composed of control computer, teaching pendant, operation panel, memory, command input/output interface, emergency stop circuit board, etc. The structure is simple and compact, and it can be flexibly matched in welding to improve welding efficiency.

Structure of Intelligent Control System of Welding Robot

3. Features of welding robot intelligent control system:

A. Welding performance is stable. To achieve the desired welding results, this requires a good match between the welding parameters and the weldment. Welding parameters such as welding current, voltage, welding speed, and arm extension play a decisive role in the welding result. The intelligent control system realizes the adjustment of welding parameters, automatically recognizes the welding seam and makes compensation.

B. Realize the automation of the welding process. The control system can intelligently reduce the welding material, and the operator only needs to hold the teach pendant away from the welding range. During the welding process, the repeated positioning accuracy is good, and the welding is stable.

C. Emergency stop operation to ensure safety. If there is a welding defect in the welding work, the intelligent control system of the welding robot will automatically send out an alarm signal and perform an emergency stop operation to protect the robot body from damage.

The control system helps the welding robot complete a series of welding tasks, effectively improving welding efficiency and stabilizing welding quality.

The above is the introduction to the welding robot intelligent control system. The intelligent control system is an important part of the welding robot, which helps the welding robot to realize the automatic welding work, improves the stability of the welding operation, clarifies the welding requirements of the product, and brings better user experience to users. Productivity.

For more information please click: