Laser cleaning principle

Apr 17,2023 | TOPTEK

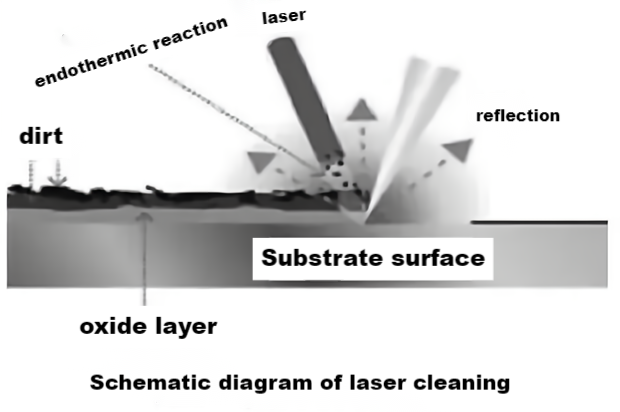

Principle of Laser cleaning

Laser cleaning uses the characteristics of high energy density, controllable direction, and strong convergence ability of the laser beam to destroy the bonding force between the pollutants and the substrate or directly vaporize the pollutants, so as to achieve the purpose of decontamination and reduction of pollutants. The bonding strength with the substrate can achieve the effect of cleaning the surface of the workpiece. The schematic diagram of laser cleaning is shown in the figure. When the pollutants on the surface of the workpiece absorb the energy of the laser, they are rapidly vaporized or expanded due to thermal expansion to overcome the force between the pollutants and the surface of the substrate. Due to the increase in heating energy, the pollutant particles vibrate and peel off from the surface of the substrate.

The entire laser cleaning process is roughly divided into four stages, namely laser gasification decomposition, laser stripping, thermal expansion of pollutant particles, substrate surface vibration and pollutant detachment. Of course, when applying laser cleaning technology, it is necessary to pay attention to the laser cleaning threshold of the object to be cleaned, and select the appropriate laser wavelength to achieve the best cleaning effect. Laser cleaning can change the grain structure and orientation of the substrate surface without damaging the substrate surface, and can also control the surface roughness of the substrate, thereby improving the comprehensive performance of the substrate surface. The cleaning effect is mainly affected by factors such as the characteristics of the beam, the physical parameters of the substrate and the dirt material, and the ability of the dirt to absorb the energy of the beam.

For more information please click:

https://www.youtube.com/watch?v=VHyqjoLTHyI

https://www.linkedin.com/company/91096732/admin/