Stainless Steel Handheld Laser Welding Machine Sheet Metal Processing

Apr 25,2023 | TOPTEK

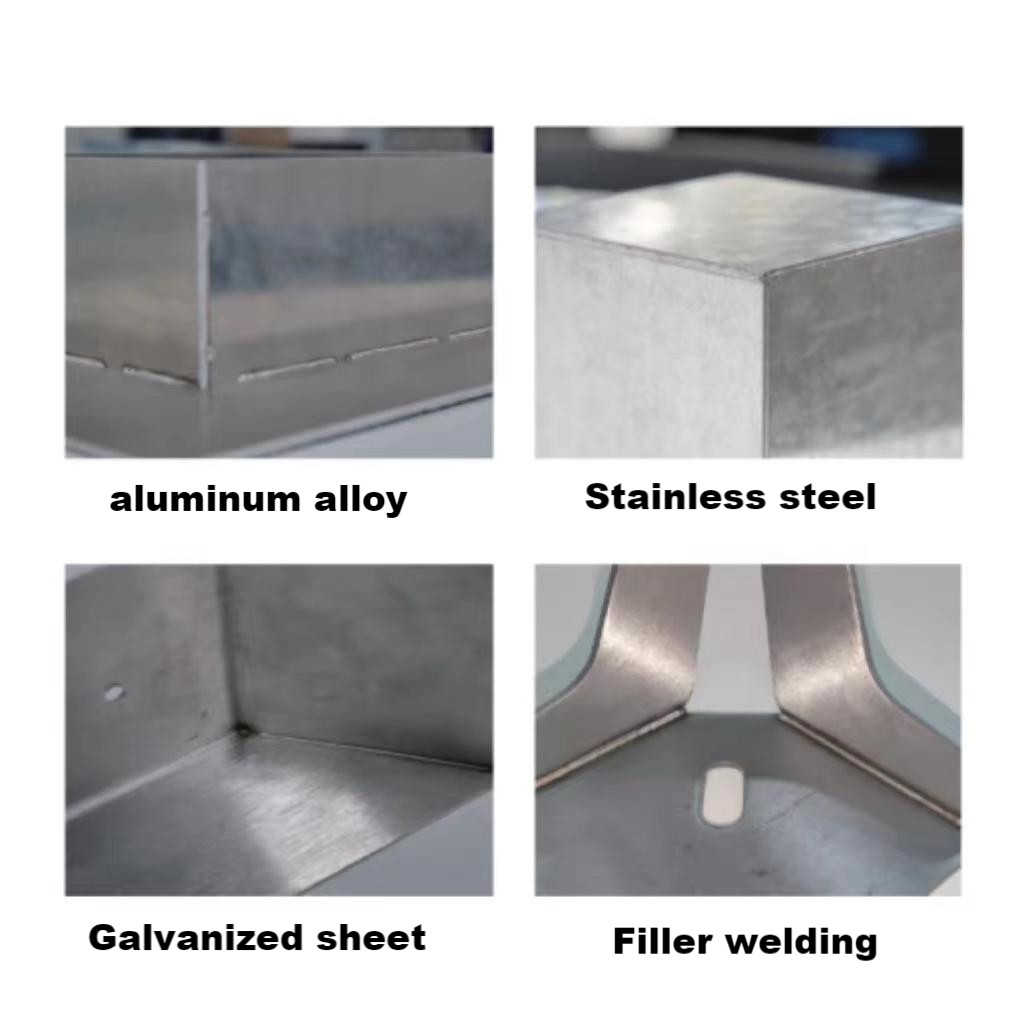

High-power laser welding machine for sheet metal parts, bottom case, sheet metal, metal parts, galvanized sheet, door handle, furniture, kettle, frame, door and window processing.

The hand-held laser welding machine replaces the fixed optical path with hand-held welding. Hand-held welding is flexible and convenient, and the welding distance is longer. It overcomes the limitation of the workbench space and is used when the workpiece size is not uniform and cannot be automatically welded. Large and complex workpieces are processed at a fixed position, the heat-affected zone is small during welding, the workpiece is not deformed, and the weld seam is firm.

The laser is mainly for thin plate welding, the workpiece is not easy to deform, and the post-processing is troublesome, and the continuous welding effect can be achieved at high frequency. The whole machine occupies a small space, the beam quality is stable, and the spot is smaller.

The hand-held welding head is selected to overcome the limitation of the workbench space, and the small metal fixed welding head is welded, and the workpiece is moved to weld, which is convenient and simple to operate. The fixed welding head can move in all directions, and the hand-held welding head can be equipped with five meters or ten meters of optical fiber. It is flexible and convenient to realize outdoor welding. It is easy to operate and can process workpieces at various angles.

The welding heat-affected zone is small, the material workpiece is not deformed, and no follow-up processing is required. High production efficiency, stable and reliable processing quality.

The laser pulse type is a power supply, and the surface heat diffuses to the inside through heat conduction. By controlling the laser pulse width, energy and other parameters, the workpiece is melted to form a specific molten pool.

For more information please click: