What is the difference between cold processing and hot processing in laser marking equipment?

Apr 26,2023 | TOPTEK

Laser technology has become more and more mature, especially in laser marking, both metal and non-metal industries can be marked. Laser marking is especially suitable for precision machining. The graphics and texts of the laser marks are delicate and beautiful, and will not be erased, and will not fade or lose color over time. It can not only improve the quality of the product, but also play the role of anti-collusion and anti-counterfeiting.

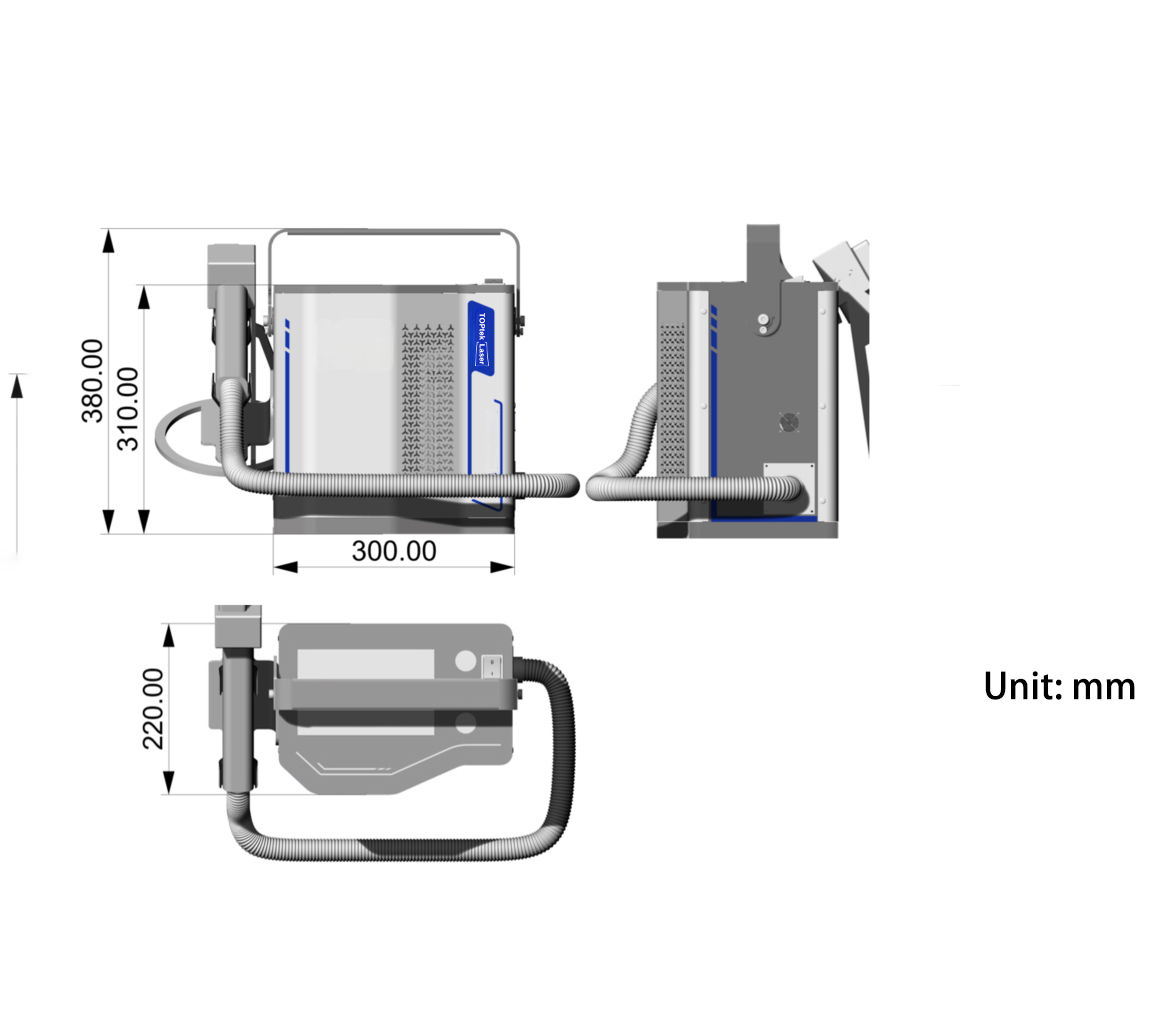

In order to meet the needs of various occupations, laser marking machines have developed the required series. Different series are aimed at different materials in different industries, and laser marking generally adopts integrated cabinet design. This design makes the laser marking machine small in size and does not take up space.

Laser marking machines are generally divided into two types: one is cold processing, and the other is thermal processing. These two processing techniques are mainly for different materials. Generally speaking, thermal processing is aimed at metal industries, while processing is aimed at laser welding equipment for plastic industries that cannot be heated.

The difference between laser marking cold processing and thermal processing:

Laser marking cold processing: Green light marking machines and ultraviolet laser marking machines generally use cold processing. Cold processing is a high-tech technology developed in recent years. It mainly irradiates the surface of the workpiece through the laser beam with high energy density, and the surface of the material absorbs the laser energy to cause non-thermal damage to the material. Because it is cold processing, it will not burn out and damage the laser welding equipment such as black edges and deformation of the workpiece.

Laser marking thermal processing: use high-energy laser beams for thermal processing to irradiate the surface of the workpiece, generate thermal reactions in the irradiated area, raise its temperature to 100%, and achieve the phenomena of combustion, dissolution, and evaporation, and then achieve our predetermined goal Effect. This laser beam is mainly used in fiber laser marking machines, CO2 laser marking machines and semiconductor laser marking machines.

Regardless of the method of cold processing or thermal processing, the contribution of laser marking machines to industrial marking is irreplaceable. The advantages of high quality, durability, inorganic pressure processing, no consumables, no pollution, no noise and assembly line production make laser marking machines an indispensable part of industrial processing, especially in today's electrical and electronic industry. The marking method is easy to fade and erase, which may lead to not knowing what type of product this product is. If the retest requires a lot of manpower and material resources, it is destined to replace the traditional marking method with a laser marking machine.

For more information please click:

https://www.youtube.com/watch?v=VHyqjoLTHyI

https://www.linkedin.com/company/91096732/admin/