What requirements do welding robots have for the accuracy of welds?

May 10,2023 | TOPTEK

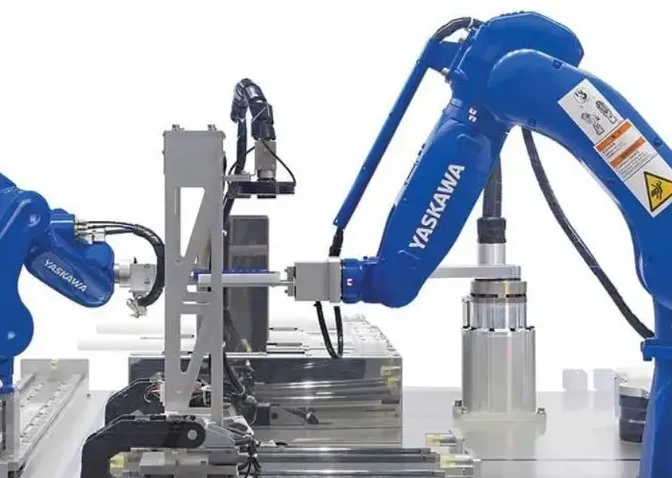

Requirements for welding seam precision of welding robots:

1. Pay attention to dimensional tolerances. The welding robot can improve the welding accuracy in the welding work. For welding seams with large tolerances, there will be welding defects such as insufficient weld filling, less welds, missing welds, and cracks. The correction process is time-consuming and labor-intensive. Therefore, in practice In the application, the dimensional tolerance of the workpiece is required to be controlled within the allowable range, which can reduce the probability of various defects in the weld and ensure stable welding.

2. Use tooling with high assembly precision. Assembly tooling is usually used in conjunction with welding robots, which can quickly fasten the workpiece, keep the workpiece in the correct position, and reduce the deformation of the workpiece during welding. Qingdao Saibang Intelligent provides high-precision assembly tooling, which can be customized according to customer needs. It is beneficial to improve the assembly accuracy of weldments;

3.Prepare a special welding process. For different welding workpieces, technicians need to choose the appropriate welding process to match, and strictly regulate the specifications, penetration depth, weld bevel position, part size, welding parameters, etc. of the weld, which is conducive to improving the quality of the weld. welding precision.

4. Adopt multi-layer and multi-pass welding. If the welding seam is large, the welding robot can use the multi-layer and multi-pass welding method. When welding, the welding path stored by the sensor is slightly offset, and the multi-layer welding can be repeated. The multi-layer welding function only needs to repeat the welding once, and the remaining The weld bead can be automatically welded.

5. Carry out cleaning work. After the welding seam is formed, if the quality inspection is qualified, it is necessary to thoroughly clean the weld bead and the robot welding torch to prevent the existence of various debris, otherwise it will affect the success rate of arc ignition.

If the accuracy of the weld seam is within the allowable range, the welding robot can improve the welding efficiency, stabilize the welding quality, and clarify the production cycle of the product. Therefore, the welding robot improves the automation and intelligence level of welding in various fields, and replaces traditional welding. The inevitable trend of welding technology development.

For more information please click:

https://www.youtube.com/watch?v=VHyqjoLTHyI

https://www.linkedin.com/company/91096732/admin/